The construction industry is a voracious consumer of materials and energy, generating vast amounts of waste. With the constant cycle of building, demolishing, and rebuilding, the quest for sustainable building materials has never been more urgent. Enter a revolutionary solution: LEGO-like concrete blocks made from recycled waste. These blocks aren’t just environmentally friendly; their innovative design makes them easy to assemble, disassemble, and reuse.

Traditional cinder blocks, while not inherently harmful, are inefficient and wasteful. Building a wall with them is labor-intensive, requiring mortar and significant effort to ensure strength. Even then, the resulting walls are not particularly strong. When a wall needs to be moved or removed, demolition is the only option, leading to further waste and resource consumption.

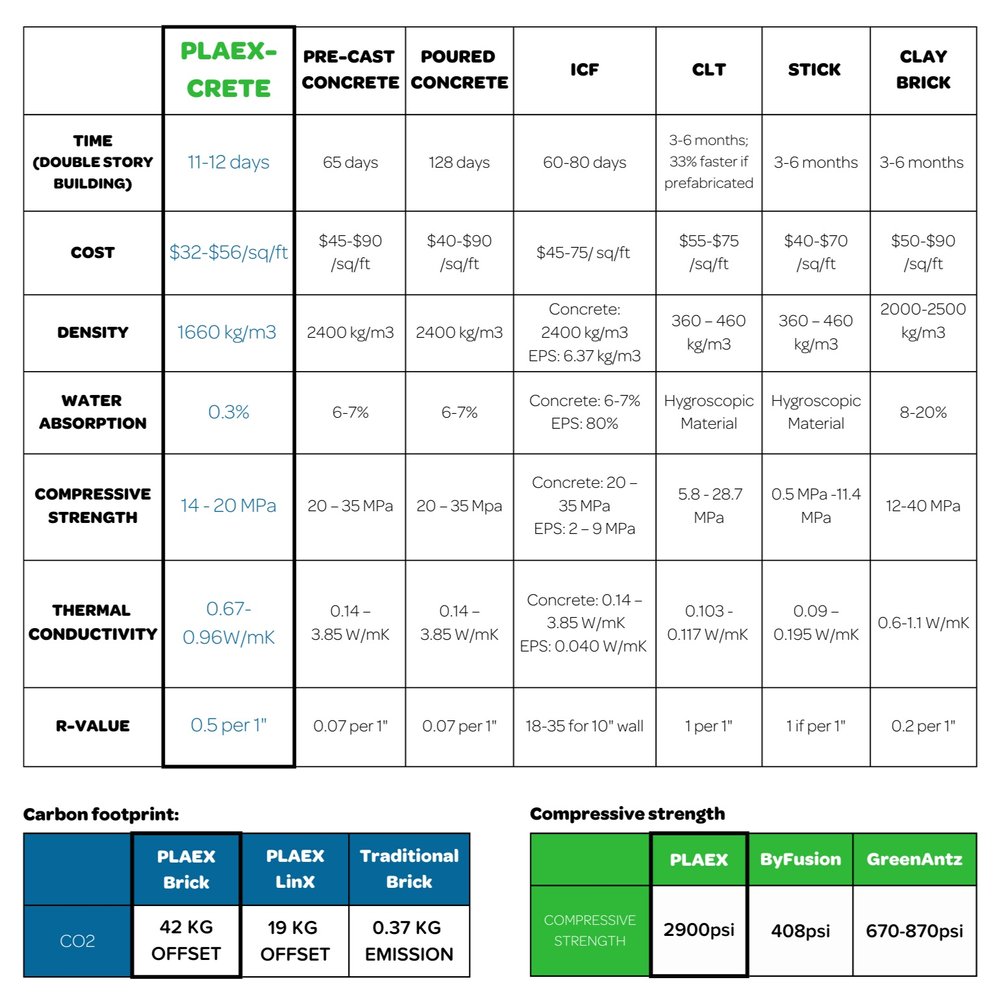

PLAEX-crete tackles these issues head-on by rethinking both the composition and construction of concrete blocks. Unlike other sustainable blocks, PLAEX-crete embraces waste materials, using over 90% recycled content, including agricultural, marine, and industrial plastic waste, as well as aggregate waste from the construction industry. Remarkably, these blocks are 33% lighter than traditional cinder blocks and even stronger.

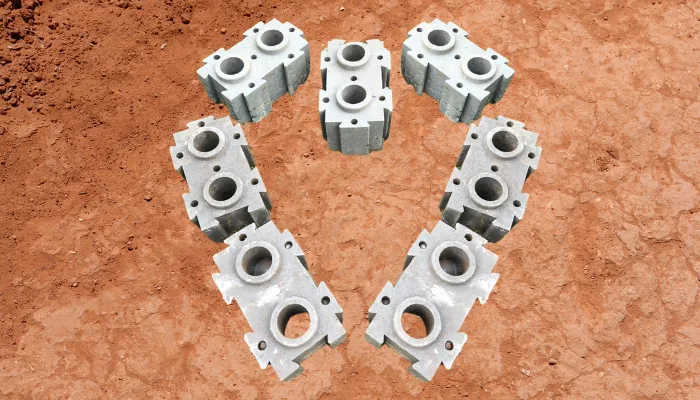

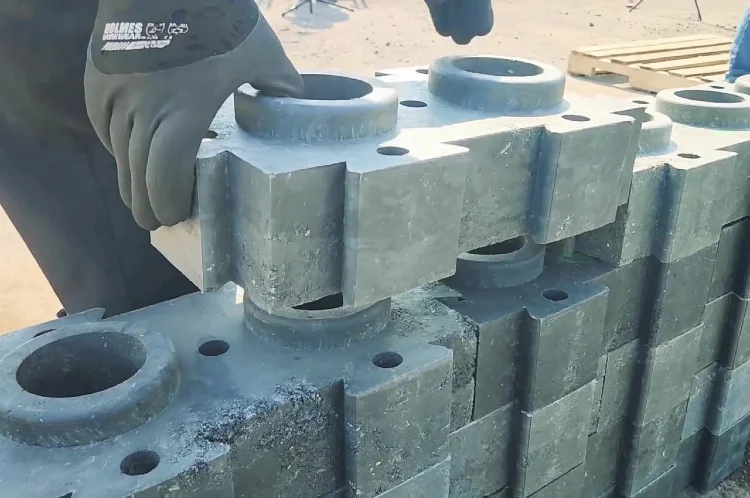

However, material innovation alone isn’t enough to transform the industry. The real game-changer is the design of the PLAEX blocks. Resembling oversized LEGO pieces, these blocks feature an interlocking mechanism that enables quick and easy assembly. This design eliminates the need for mortar, allowing walls to be constructed in half the time it takes with traditional blocks. Despite the absence of mortar, the walls are more solid, sturdy, and durable than their conventional counterparts.

The interlocking design also facilitates easy disassembly, making it possible to reuse the blocks for other projects, thereby saving money and resources. PLAEX has even expanded this concept with the PLAEX LinX, which supports connections at different angles for more creative and flexible constructions.

Currently, PLAEX blocks are limited to non-occupancy walls, but work is underway to achieve certification for homebuilding. Once this is achieved, it could revolutionize the construction industry, offering a sustainable and efficient alternative to traditional building materials.

How PLAEX-Crete is More Sustainable

PLAEX-crete stands out in sustainability by using waste materials that would otherwise contribute to pollution and landfill. By incorporating agricultural, marine, and industrial plastic waste, PLAEX-crete not only reduces the need for new raw materials but also addresses the issue of waste management. The blocks’ lightweight nature reduces transportation emissions, further lowering their environmental impact.

The interlocking design reduces the need for additional materials like mortar, which means fewer resources are consumed during construction. This design also ensures that the blocks can be reused, reducing waste and promoting a circular economy within the construction industry.

The Broader Impact

More To Discover

- The United Arab Emirates Just Took Over Entire Forests in Africa To Greenwash Their Way To Carbon Credits

- Green Energy’s Uptick: A Silver Lining with a Cloudy Forecast

- The Future of Eggs Is Here: Precision Fermentation Means Flocks Won’t Need To Produce Eggs

- Turning Insects Into a Sustainable Solution: The Potential of Bioplastics from Flies

PLAEX-crete is changing the game in construction. By transforming waste into valuable building blocks, it addresses the pressing environmental concerns of traditional methods. Imagine constructing entire buildings from recycled materials, significantly reducing pollution and carbon emissions. This vision is becoming a reality with PLAEX-crete, paving the way for a more sustainable future in construction.

As PLAEX-crete moves towards certification for residential use, its potential impact grows. This isn’t just about building walls; it’s about redefining how we approach construction. Each block is a testament to the power of recycling and resource efficiency, making eco-friendly building practices not just feasible but highly desirable. With every new project, PLAEX-crete is setting a new standard for sustainability in the industry.