Mary Lempres, an industrial designer, has spearheaded an eco-conscious shift in construction with her brainchild, the Reef Rocket. This isn’t just another piece in the sustainability puzzle; it’s a game-changer in our battle against coastal flooding, dwindling biodiversity, and the growing specter of climate change.

Crafted from bio-cement, the Reef Rocket doesn’t just stand strong against the elements; it filters seawater and fosters life, emulating the mighty yet delicate oyster reefs.

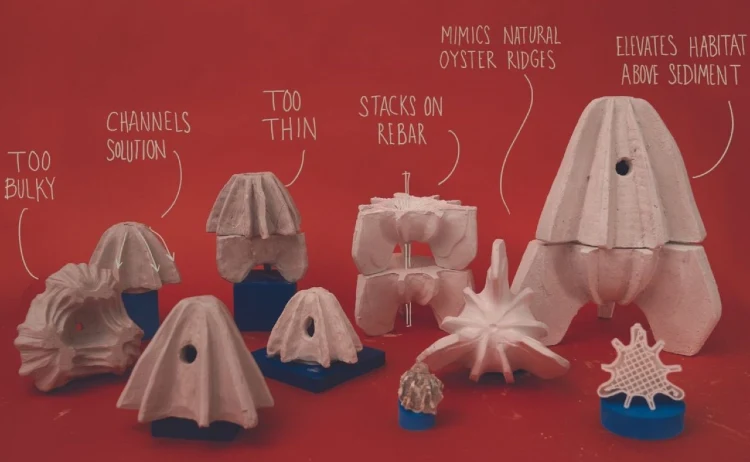

Picture this: two modules, each sculpted with ridges and grooves, coming together underwater to form a rocket-like structure. It’s an artful blend of natural inspiration and human ingenuity, a testament to biomimicry – our attempt to emulate nature’s genius in our designs. Lempres, in collaboration with bio-geotechnical specialist Ahmed Miftah, has concocted a plant-based cement that grows, akin to how plants are nurtured in irrigation systems.

Now, let’s delve into the nitty-gritty.

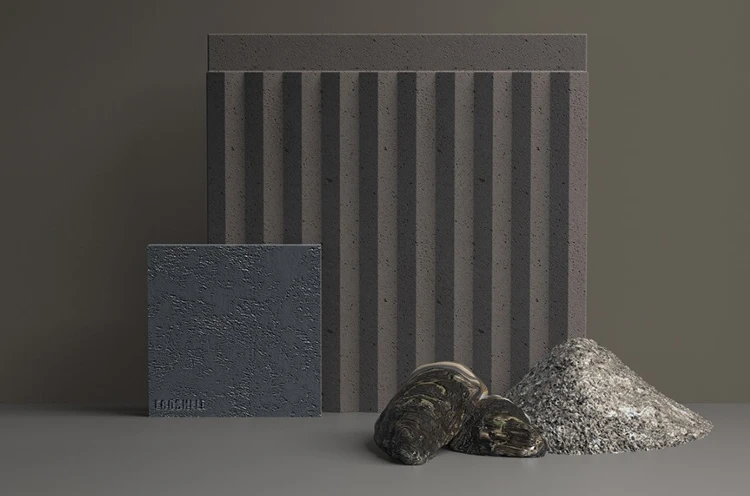

The bio-cement in question is born from a mix of plant extracts and a non-toxic solution, poured over an aggregate of crushed glass and oyster shells – a nod to sustainability, sourcing materials from local eateries and the New York Harbor.

This concoction, left to saturate for a few days, transforms into a natural concrete. Think of it as minerals playing connect-the-dots, creating bridges between glass and shell fragments. The outcome? A sturdy, water-resistant material that rivals traditional concrete but with an eco-friendly twist.

Reef Rocket is revolutionary in its simplicity and sustainability. No need for heat or fossil fuels here; this bio-cement thrives in any setting. It’s not just about being green; it’s about being practical and accessible. The materials share a chemical kinship with the substances oysters use to construct their homes, yet the Reef Rocket speeds up the process from millennia to mere days.

After rigorous experimentation and “hundreds” of prototypes, Lempres’s team found their sweet spot with prefabricated molds. These molds are the magic wands of this project, allowing the bio-cement to set without any heat or harmful chemicals. It’s a process that’s as kind to the environment as it is efficient.

So, what’s the real magic of Reef Rocket?

It lies in its scalability and potential. Lightweight, easy to assemble, and small in stature, this bio-cement structure is poised to become a staple in sustainable construction. Lempres dreams of a world where materials grow like crops, where waste finds new life, and where human infrastructure coexists harmoniously with nature.

Reef Rocket isn’t just a product; it’s a vision. It’s a bold statement in sustainable design, showing us that we can tackle climate change and ecological challenges by looking to nature for answers. It’s a step towards a future where our creations don’t just serve us but serve the planet as well.

Now, to further understand the sustainability of Reef Rocket compared to traditional cement, we delve into the eco-friendly aspects of its production and use. Traditional cement production is a major contributor to carbon emissions, primarily due to the energy-intensive process of heating limestone and clays to high temperatures. In stark contrast, bio-cement like that used in Reef Rocket eliminates the need for such heating, significantly reducing carbon emissions.

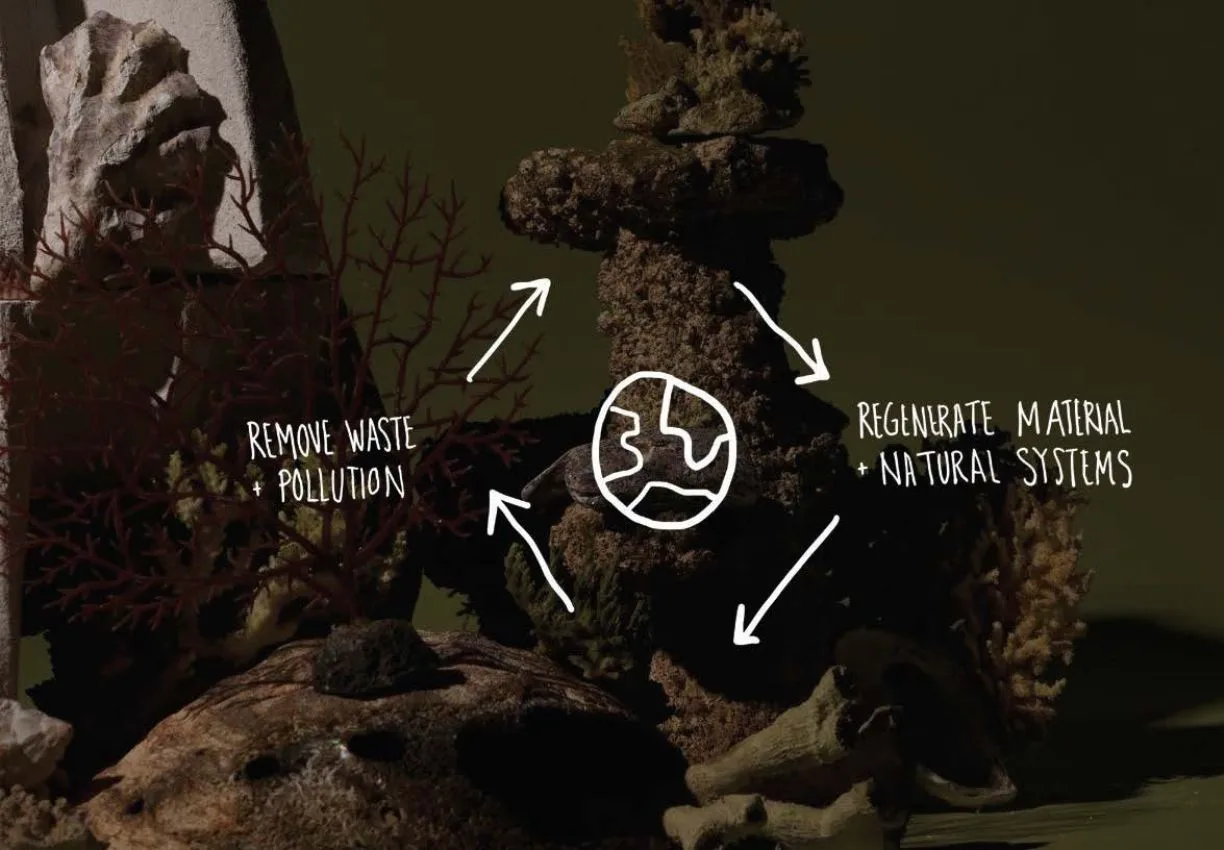

Moreover, the use of recycled materials like crushed glass and oyster shells in Reef Rocket’s composition not only diverts waste from landfills but also lessens the need for virgin materials typically used in cement production. This approach embodies the principles of a circular economy, where waste becomes a resource, thus reducing the environmental impact.

Statistically speaking, the cement industry is responsible for about 8% of the world’s CO2 emissions.

More To Discover

- Alaska Triumphs in Emission Reduction with a Simple, Local Carbon Offset Project That Actually Works

- Suing for Survival: Legal Battle to Prevent the Great Salt Lake from Turning to Toxic Dust

- 10 Reasons Why Passive Houses Are the Future of Energy-Efficient Living

- Hottest Year in 125,000 Years, Yet #ClimateScam Trends: Why Climate Change Denial Persists Despite Overwhelming Evidence

By replacing regular cement with bio-cement, like Reef Rocket in construction, we could potentially cut down a substantial amount of these emissions. Additionally, the energy savings from not having to heat materials during the production of bio-cement are significant. For instance, traditional cement production can reach temperatures up to 1450°C, consuming considerable amounts of energy, whereas bio-cement production occurs at ambient temperatures.

In summary, Reef Rocket’s bio-cement is a shining example of how innovative, sustainable design can lead us towards a more environmentally friendly future in construction and urban planning. By harnessing the power of biomimicry and circular economy principles, it offers a practical, scalable, and ecologically sound alternative to traditional building materials.