Back in early December 2023, during the Marintec China Expo in Shanghai, the China State Shipbuilding Corporation (CSSC) turned heads by unveiling the KUN-24AP containership. It’s not just the world’s largest container ship, boasting an enormous 24,000 TEU capacity, but what really got everyone talking is its power source. This giant of the seas is set to be propelled by a molten salt reactor, designed by Chinese engineers, and powered by a thorium fuel cycle.

Now, why is this such a big deal? Well, not only does this reactor provide the massive electrical power needed to move this colossal vessel, but it also brings a breath of fresh air to the environment. It eliminates harmful emissions, which is a win for our planet, and it’s rumored to make the ship faster than its conventional counterparts.

But hold on, there’s more to this story.

The Norwegian classification society, DNV, has already given the nod of approval to CSSC Jiangnan Shipbuilding shipyard. This green light signals that we might soon witness the launch of this groundbreaking ship. Now, we know that the shipping industry has been grappling with a drop in demand and an oversupply of conventionally powered vessels, a situation exacerbated by the surge in demand in 2020. So, this innovative container ship could be the game-changer the industry desperately needs to adapt to today’s economic reality.

But, of course, there’s still a lot we don’t know about the KUN-24AP. The details about the molten salt reactor are shrouded in secrecy, leaving us with many questions about how it all fits into the grand scheme of nuclear marine propulsion.

A Different Perspective on the Old Nuclear Marine Propulsion

So, we’ve talked about the KUN-24AP containership and how it’s shaking up the shipping world with its cutting-edge molten salt reactor. But here’s the thing: the concept of nuclear marine propulsion isn’t exactly new. In fact, it’s been around since the inception of nuclear reactors. Over the decades, we’ve seen various attempts at harnessing nuclear power for ships, but success has been somewhat elusive in certain sectors like commercial shipping and passenger liners. On the other hand, when it comes to projecting military might across the seas, nuclear propulsion reigns supreme. Diesel-electric submarines and conventionally powered aircraft carriers fall short in terms of range and capability.

The secret sauce here lies in the staggering energy density of nuclear fuel. Depending on the reactor’s setup, a vessel can go for years, even decades, without needing to refuel – a feat unmatched by traditional means. Take U.S. nuclear-powered aircraft carriers, for instance; they undergo refueling roughly every 20 years during their midlife shipyard overhaul. This involves lifting out the entire reactor module through a deck opening and replacing it with a fresh one. With an abundance of power at their disposal, there’s no need to skimp on fuel, allowing these warships to fully push their limits.

Now, in theory, this same advantage could extend to civilian merchant vessels like tankers, cargo ships, and container ships. However, the reality is quite different. The only active player in this field is the Soviet-era Sevmorput, which serves under Rosatom’s Atomflot alongside nuclear-powered icebreakers. Launched in 1986, Sevmorput is set to retire in 2024 after a long and, ironically, somewhat obscure career. Despite regularly shuttling between various Russian ports, including those on the Baltic Sea, few people today even know it exists.

The Sevmorput houses a KLT-40 nuclear reactor (135 MWth), a design like the one found on U.S. aircraft carriers like the USS Nimitz (with two A4W reactors providing 550 MWth). Both are pressurized water reactors (PWRs), somewhat akin to the ones you’d find in most commercial nuclear power stations worldwide. The main difference lies in the uranium fuel’s enrichment, which dictates the refueling schedule.

Now, this is where the KUN-24AP container ship takes a radical turn with its molten salt reactor (MSR). It might seem like an unconventional choice, but there’s a method to this madness. MSRs come with inherent safety features, the ability to refuel continuously without reactor shutdowns, and a high burn-up rate, which means minimal waste to be filtered from the molten salt fuel. The roots of this innovative reactor can be traced back to China’s TMSR-LF program, with the TMSR-LF1 reactor receiving its operating permit in 2023. This reactor is a fast neutron breeder, capable of producing U-233 from thorium (Th-232) through neutron capture, allowing it to primarily run on more cost-effective thorium instead of uranium fuel.

But Does This Actually Make A Difference?

Building a massive container ship? Not the real challenge here. The recent surge in New Panamax and larger container vessels, like the mammoth ~24,000 TEU Evergreen A-class, proves that point. The real conundrum lies in getting this colossal ship to move gracefully and effectively through the water.

If you want a direct drive shaft to power the propeller, you need an ample supply of shaft power. Achieving this requires a power plant that can deliver the required torque either directly or through a gearbox. There are a couple of options: you can opt for a hefty generator coupled with electric propulsion, or you can go the route of boilers and steam turbines. Now, while boilers and steam turbines pack a punch in terms of versatility and power, they come with a hefty price tag when it comes to operation and maintenance.

Take, for instance, the Evergreen G-series container ships, which are fitted with a 75,570 kW combustion engine. In contrast, the Kitty Hawk boasts a whopping 210 MW, and the Nimitz isn’t too far behind with 194 MW of installed power. The Nimitz’s two A4W reactors churn out ample steam, providing 104 MW for each pair of propellers, leaving a substantial surplus of several hundred MW for the ship’s various systems.

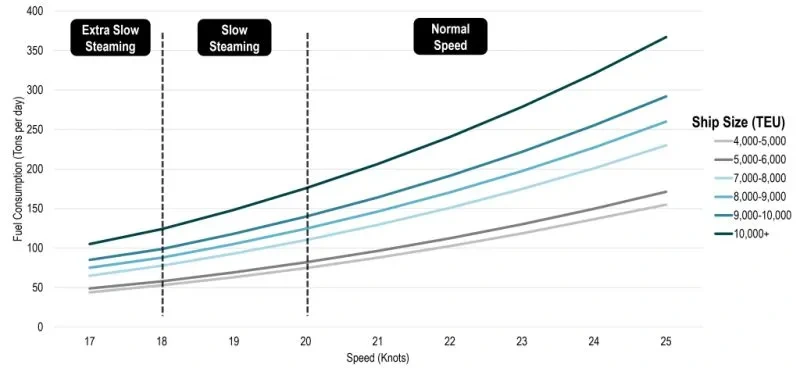

Thanks to this generous power supply, these aircraft carriers can reach speeds of up to 32 knots. On the other hand, standard container ships tend to cruise at more moderate speeds, ranging from 15 to 25 knots. The cost of fuel becomes a significant factor in this decision. Opting for faster speeds can lead to considerably higher fuel consumption, which is why many container ships often settle for a more economical pace, typically around 18-20 knots, when time permits.

While fuel efficiency is also a concern for conventionally powered ships like the Kitty Hawk, the nuclear-powered Nimitz boasts virtually unlimited fuel for 20-25 years. This freedom from fuel constraints allows it to travel at any speed its crew and ship can handle, making it a true maritime powerhouse.

Full Speed Ahead: How This May Impact The Future of Shipping

Now, as we’ve discussed earlier, the shipping industry has found itself in a tight spot, even before recent events that disrupted the Panama and Suez canals, forcing cargo ships to take lengthy detours around Africa and South America—a throwback to the early 19th century shipping routes. Imagine, though, if cargo ships could cruise at speeds of 30 knots or more instead of the usual 20.

Suddenly, the circumnavigation of Africa, rather than navigating the Suez Canal, becomes a much shorter and more flexible journey. And if this could be achieved without a hefty fuel cost penalty, you’ve got the rapt attention of every shipping company on the planet. This is precisely where the KUN-24AP containership’s debut starts making a lot of sense.

Of course, when you throw around the term ‘nuclear power,’ concerns naturally arise.

Yet, decades of experience with nuclear propulsion have shown that the biggest risk often isn’t the technology itself, but the resistance against adopting nuclear marine propulsion.

Various commercial vessels, like the Mutsu, Otto Hahn, and Savannah, found themselves retired or converted to diesel propulsion not due to accidents but rather due to harbors refusing access solely because of their nuclear propulsion.

This situation leaves the Sevmorput as the lone survivor of that era, outside of vessels operated by the world’s naval forces. Interestingly, naval forces have had their share of sunken nuclear-powered submarines resting peacefully on the ocean floor, without any catastrophic effects.

While many details about the KUN-24AP and its power plant remain shrouded in mystery, one thing is clear: the TMSR-LF-derived MSR is likely designed to be highly automated. The addition of fresh thorium salts and the filtration of gaseous and solid waste products may not require human intervention or constant monitoring.

Given that conventional container ships already have engineering crew members overseeing combustion engines and various systems, this arrangement is likely to be maintained, albeit with some necessary (re)training to operate the new propulsion system effectively.

More To Discover

- Court Halts Dicamba Use, Citing Unlawful EPA Approval

- Safest Energy Sources: A Comprehensive Guide to Impact and Sustainability (Wind, Solar, Fossil Fuels, Hydro, Nuclear)

- The Future of Our Cities: Powered by… Toilet Water?

- Mystery Solved: Floating Object off Washington Coast Revealed as Renewable Energy Prototype

The winds of change are blowing, and it seems we’re on the cusp of a new era. Samsung Heavy Industries, another heavyweight in the shipping world, already expressed interest in 2021 for nuclear power plant technology based on molten salt reactors.

The day when container ships quietly glide into harbors worldwide without belching exhaust gases might be closer than we think.

With growing acceptance from insurance companies and harbor operators, we may be witnessing the dawn of a revolution, one that will reshape the way we view the future of shipping.